-

Equipment Stands

Just wondering what type of equipment stands you guys have come across, my MSA 72 griddles weigh about 800 lbs.

What I see is essentially 6 sticks of pipe with 2 shelfs on it and they slide stem casters into the pipe and that’s that.

Casters probably rated for 200 lbs a piece or so, 6 casters, 1200 lbs total capacity, throw an uneven floor in there and you probably have 600-1000 lbs of capacity, take in the rolling load and all the moving the griddle around and shifting weight on the raceway of the caster and, well it ain’t pretty.

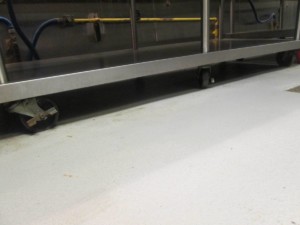

Here’s what it turns out to be.

Not very nice.

Here’s what it became after coming out of my shop.

450 lbs casters, total capacity is 2700 lbs, with the curved floor, 2 wheels don’t touch the floor so it becomes only 1800 lbs capacity, good enough for me.

You may be thinking “Noo, the wheels weren’t installed properly, that’s why they stick out!” I already re installed those wheels, 2 times.

This is how it should be done, all stainless tubing, all TIG welded, 140 grit finish, all stainless bolts, washers and nuts.

What type of stands do you guys see? This one looked like it was ready to topple over and land the griddle on someone. Looked very dangerous and definetley not something I trust, was the one we got just a piece of crap or is it the industry standard?

Log in to reply.